Soundproof Shed Plans: The Perfect Shed for Music or Work

The pursuit of a dedicated space for creative endeavors or focused work often necessitates a solution that minimizes external noise interference. For musicians, hobbyists, or individuals requiring a quiet workspace, a soundproof shed presents an ideal solution. This comprehensive guide delves into the meticulous planning and construction required to build a highly effective soundproof shed, ensuring a peaceful and productive environment.

Planning Your Soundproof Shed

Before commencing construction, meticulous planning is paramount. This stage involves careful consideration of several crucial factors that will directly impact the shed's effectiveness and longevity.

Site Selection and Foundation

The location of your soundproof shed significantly influences its acoustic performance. Avoid areas prone to high levels of ambient noise, such as proximity to busy roads or industrial zones. A stable and level foundation is crucial. Concrete is the preferred choice, providing a robust base that minimizes vibrations. Consider engaging a professional surveyor to assess soil conditions and ensure proper foundation design.

Dimensions and Design

The dimensions of your shed should be carefully considered based on your intended use. Sufficient space must be allocated to accommodate your equipment, instruments, or work materials, while ensuring comfortable movement. A compact design minimizes surface area, thus reducing sound transmission. Simple, rectangular designs generally offer superior acoustic performance compared to complex shapes.

Materials Selection: The Cornerstone of Soundproofing

The choice of building materials directly impacts the shed's soundproofing capabilities. Selecting materials with high mass and density is crucial to effectively attenuate sound waves. The following materials are commonly used in soundproof construction:

- Walls: Double-stud walls with staggered studs, filled with dense insulation (e.g., mineral wool, rock wool), and faced with heavy drywall (e.g., 5/8" or denser) are highly effective. Consider adding a layer of mass-loaded vinyl (MLV) between the drywall layers for enhanced sound absorption.

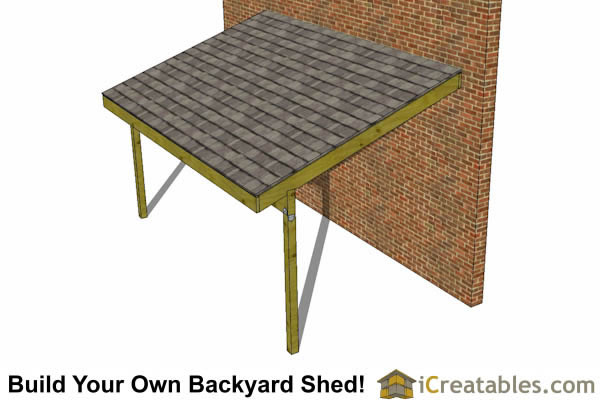

- Roof: Similar principles apply to the roof construction. A double-layered roof with staggered rafters, dense insulation, and heavy roofing material (e.g., asphalt shingles with added underlayment) will significantly reduce noise transmission.

- Floor: A concrete slab foundation provides excellent sound insulation. Adding a resilient layer, such as decoupling mats, between the concrete and the subfloor further improves vibration damping.

- Doors and Windows: These represent significant weak points in soundproofing. Solid core doors with robust weatherstripping are essential. Consider using double or triple-glazed windows with laminated glass and airtight seals. Solid wood doors are significantly more effective than hollow-core doors.

Construction Process: Building Your Soundproof Haven

The construction process requires meticulous attention to detail. Each stage must be executed precisely to ensure optimal soundproofing.

Foundation and Framing

Begin by preparing the site and pouring the concrete foundation. Allow ample curing time before proceeding. The framing of the walls and roof should be constructed using pressure-treated lumber for durability and resistance to moisture. Accurate measurements and precise cuts are vital to ensure a secure and airtight structure. Staggering the studs in the double-wall construction is critical for breaking sound bridges.

Insulation and Drywall Installation

Once the framing is complete, install the chosen dense insulation materials within the wall cavities. Pay close attention to sealing any gaps or cracks to prevent sound leaks. The installation of drywall should be meticulous, ensuring tight seams and proper fastening. Adding a layer of MLV between drywall layers significantly enhances sound attenuation. Repeat this process for the roof and floor, paying particular attention to sealing all joints and penetrations.

Door and Window Installation

Install the chosen doors and windows, ensuring a tight seal to minimize sound leakage. Use high-quality weatherstripping and caulking to effectively block any gaps. Consider using sound-dampening gaskets around the frames for added protection. Proper installation of these elements is crucial for the overall effectiveness of the soundproofing.

Finishing Touches

Once the primary construction is complete, attention should be given to finishing touches that enhance both the acoustic performance and the overall aesthetics of the shed. This might include applying acoustic panels to walls or ceilings to absorb sound reflections, installing sound-dampening curtains, and choosing appropriate flooring materials to reduce impact noise.

Advanced Soundproofing Techniques

For those seeking exceptional levels of sound isolation, several advanced techniques can be incorporated into the design and construction.

Decoupling

Decoupling the structure from its foundation and surrounding environment minimizes the transmission of vibrations. This involves creating a break in the structural path of sound transmission. Methods include using resilient channels for drywall installation, decoupling the floor from the foundation with vibration-damping mats, and employing independent floating walls.

Sound Absorption

Sound absorption reduces sound reflections within the shed, minimizing echoes and reverberation. Strategically placed acoustic panels made of porous materials such as acoustic foam or mineral wool can effectively absorb sound energy. The placement and quantity of these panels should be determined based on the size and shape of the shed.

Sound Dampening Materials

Incorporating sound-dampening materials such as mass-loaded vinyl (MLV) within the wall and ceiling construction significantly enhances soundproofing. MLV acts as a barrier to sound waves, reducing transmission through the structure. Its placement between layers of drywall maximizes its effectiveness.

Conclusion

Building a soundproof shed is a rewarding project that provides a dedicated space for focused work or creative pursuits. By carefully planning the design, selecting appropriate materials, and meticulously executing the construction process, you can achieve a high level of sound insulation. Remember that attention to detail is paramount. Every gap, crack, or poorly sealed joint can significantly compromise the effectiveness of the soundproofing. With careful planning and execution, you can create a peaceful and productive sanctuary, free from unwanted noise.